Contact Us

Contact Us

Guangzhou Huaisheng Packaging Co.,Ltd.

We provide customers with quality products and provide high-quality services.

If you would like to leave us a comment please go to contact us

+86-18122240089

In the packaging industry, understanding the Box Maker's Certificate (BMC) is essential for ensuring the quality and performance of corrugated boxes. Whether you are a manufacturer or a consumer, comprehending the information on a BMC can help you select the right packaging solutions for your needs. This article will guide you through the components of a BMC and explain its significance.

A Box Maker's Certificate (BMC) is a label found on corrugated boxes that provides detailed information about the box's manufacturing specifications and its strength. This certificate is crucial for maintaining quality control and compliance with industry standards. By understanding the BMC, you can make informed decisions about packaging and ensure the safe transportation of goods.

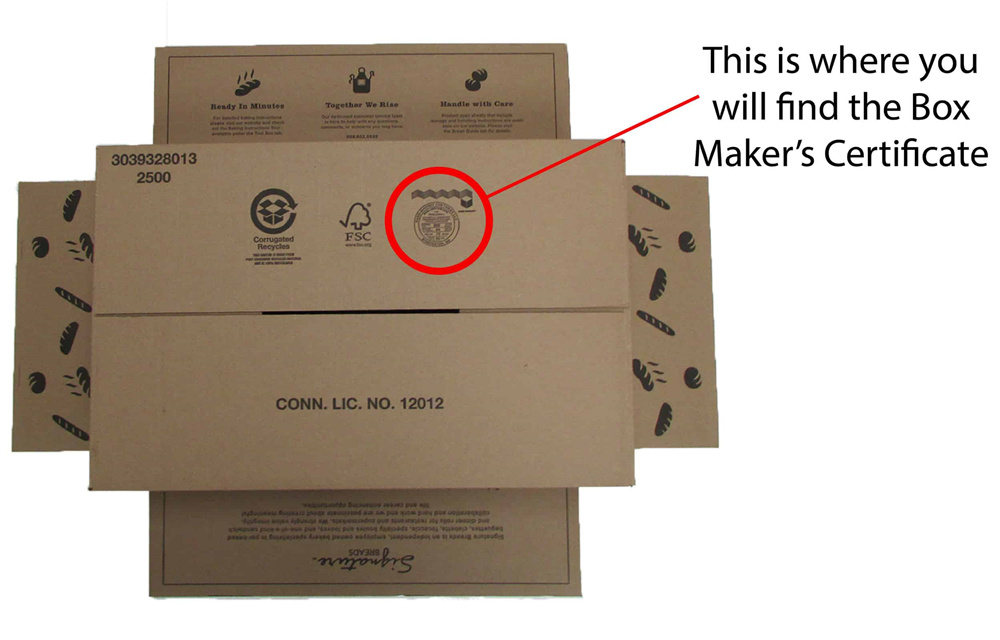

The BMC is typically located on the bottom or side of a corrugated box. It appears as a stamp or printed label and contains vital information about the box's construction and performance characteristics. Recognizing and understanding this certificate is the first step in ensuring you choose the right box for your needs.

One of the primary elements of a BMC is the manufacturer's information. This includes the name and address of the company that produced the box. Knowing the manufacturer can provide insights into the quality and reliability of the box, as reputable manufacturers adhere to stringent industry standards.

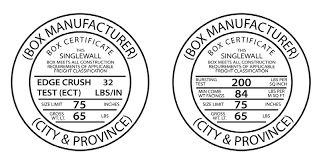

The BMC also includes detailed box specifications, such as the type of corrugated board used (single-wall, double-wall, or triple-wall), the flute type, and the box's dimensions. These specifications help determine the box's suitability for various applications and its ability to protect the contents during shipping and handling.

Understanding the strength ratings on a BMC is crucial for selecting the right box. Two key metrics are often included:

The BMC also specifies the maximum weight the box can safely hold. This information is vital for ensuring that the box can handle the load without compromising its integrity. Overloading a box beyond its weight limit can lead to damage and potential product loss during transit.

A certification mark on the BMC indicates compliance with industry standards and regulations. This mark assures that the box has been tested and meets the required specifications for strength, durability, and safety. Common standards include those set by the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO).

Burst strength is a critical measure of a box's durability. It indicates the ability of the box to resist internal and external pressure without rupturing. For example, a box with a burst strength of 200 psi can withstand pressures up to 200 pounds per square inch before breaking. This rating is particularly important for boxes used in environments where they may be subjected to high pressure or sharp objects.

The Edge Crush Test (ECT) rating is another essential measure of a box's strength. It assesses the box's ability to withstand crushing forces applied to its edges. For instance, a box with an ECT rating of 32 lb/in can endure a force of 32 pounds per inch applied to its edges. This rating is crucial for boxes that will be stacked during storage or transportation, as it indicates how well the box can maintain its structural integrity under load.

Compliance with industry standards is vital for ensuring the quality and safety of corrugated boxes. The BMC often includes certification marks that signify adherence to these standards. Some of the common standards include:

By adhering to these standards, manufacturers can ensure that their boxes meet the required specifications and provide reliable protection for the contents.

When selecting a corrugated box, it is essential to consider the information on the BMC. Ensure that the box's strength ratings (burst strength and ECT) meet the requirements of your application. Additionally, verify that the box's specifications, such as dimensions and type of corrugated board, are suitable for your needs.

Always adhere to the maximum weight limit specified on the BMC. Overloading a box beyond its weight limit can compromise its structural integrity and lead to damage during transit. If your packaging needs exceed the weight limit, consider using a stronger box or multiple boxes to distribute the load.

Consider the environmental conditions the box will be exposed to during storage and transportation. Factors such as humidity, temperature, and handling methods can impact the performance of the box. Choosing a box with appropriate strength ratings and specifications can help mitigate these risks and ensure the safe delivery of your products.

Understanding the Box Maker's Certificate is essential for selecting the right corrugated box for your packaging needs. By comprehending the components of the BMC, such as manufacturer information, box specifications, strength ratings, maximum weight limit, and certification marks, you can make informed decisions and ensure the safe transportation of your goods. Always consider the BMC when choosing packaging solutions to maintain quality, compliance, and reliability in your shipping and storage operations.

If you want to know more about packaging boxes, click here to see more>>