Contact Us

Contact Us

Guangzhou Huaisheng Packaging Co.,Ltd.

We provide customers with quality products and provide high-quality services.

If you would like to leave us a comment please go to contact us

+86-18122240089

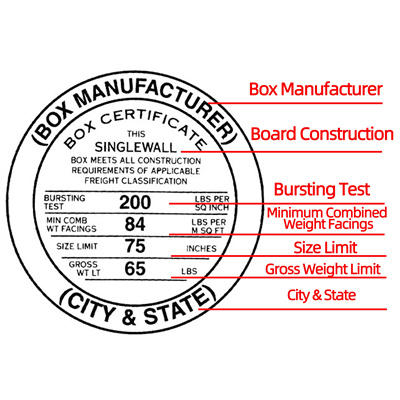

The Box Maker's Certificate (also named as box manufacturer certificate) is a stamp or label commonly found on corrugated boxes that provides important information about the box's construction and strength. The certificate indicates that the box conforms to certain standards set by organizations such as the International Safe Transit Association (ISTA) or the American Society for Testing and Materials (ASTM). The BMC is particularly relevant for shipping and packaging industries where the integrity of a box during transit is critical.

The BMC is a quality assurance mark that proves that the various physical properties of the current carton meet or exceed the index stated on the quality assurance seal. Its function is to illustrate The current cartons meet the transportation requirements and are suitable for transportation.

Strictly speaking, the carton quality assurance seal is only a stipulation on the physical properties of the carton, not the entire quality. For example, it does not include printing graphics and text effects, size specifications, waterproof and moisture-proof properties, etc.

Box Manufacturer: This identifies the company that produced the box. It may include the manufacturer's name, logo, or a specific code that can be traced back to the company. This information is crucial for accountability and quality assurance purposes.

Board Construction: This describes the type of corrugated board used to make the box. It indicates the flute size (e.g., A, B, C, E, or F flutes) and the number of walls (single-wall, double-wall, or triple-wall). Flute size affects the box's stacking strength and insulation properties, while the number of walls impacts the overall durability and protective qualities of the box.

Bursting Test: Also known as the Mullen Test, this is a measure of the box's resistance to rupture under pressure. The result is expressed in pounds per square inch (psi). A higher bursting test value indicates a stronger box that can withstand more internal or external force without failing.

Minimum Combined Weight Facings: This refers to the combined weight of the linerboard materials used on the inner and outer facings of the corrugated board. It is measured in pounds per thousand square feet (MSF). This weight influences the box's puncture resistance and overall strength.

Size Limit: This specifies the maximum external dimensions a box can have (length, width, and depth) to maintain its certification. It ensures that the box's size is appropriate for the strength characteristics indicated on the BMC.

Gross Weight Limit: This is the maximum weight the box is certified to hold and transport safely. It is an important consideration for shippers to prevent overloading and potential box failure.

City & State: This indicates the location of the manufacturing facility where the box was produced. This can be relevant for tracing the source of the boxes and for logistical considerations.

Quality Assurance:

Regulatory Compliance:

Informed Decision Making:

Consistency and Standardization:

Single-wall corrugated fiberboard boxes

| Gross Wt.Lt(Lbs) | Size Limit (in) |

Min comb wt Facings Lbs/M sq.ft(g/m2) |

Bursting Test(Lbs/sq.In) | ECT(Lbs/In) |

| 20 | 40 | 52(254) | 125 | 23 |

| 35 | 50 | 66(322) | 150 | 26 |

| 50 | 60 | 75(366) | 175 | 29 |

| 65 | 75 | 84(410) | 200 | 32 |

| 80 | 85 | 111(542) | 250 | 40 |

| 95 | 95 | 138(674) | 275 | 44 |

| 120 | 105 | 180(879) | 350 | 55 |

Double-wall corrugated fiberboard boxes

| Gross Wt.Lt(Lbs) | Size Limit (in) |

Min comb wt Facings Lbs/M sq.ft(g/m2) |

Bursting Test(Lbs/sq.In) | ECT(Lbs/In) |

| 80 | 85 | 92(449) | 200 | 42 |

| 100 | 95 | 110(537) | 275 | 48 |

| 120 | 105 | 126(615) | 350 | 51 |

| 140 | 110 | 180(879) | 400 | 61 |

| 160 | 115 | 222(1084) | 500 | 71 |

| 180 | 120 | 270(1318) | 600 | 82 |

Triple-wall corrugated fiberboard boxes

| Gross Wt.Lt(Lbs) | Size Limit (in) |

Min comb wt Facings Lbs/M sq.ft(g/m2) |

Bursting Test(Lbs/sq.In) | ECT(Lbs/In) |

| 240 | 110 | 168(820) | 700 | 67 |

| 260 | 115 | 222(1084) | 900 | 80 |

| 280 | 120 | 264(1289) | 1100 | 90 |

| 300 | 125 | 360(1758) | 1300 | 112 |

If you want to know more about carton packaging, just follow Huaisheng Packaging