Contact Us

Contact Us

Guangzhou Huaisheng Packaging Co.,Ltd.

We provide customers with quality products and provide high-quality services.

If you would like to leave us a comment please go to contact us

+86-18122240089

Get Custom Quote

Call Now: +86 13824426818

|

DetermineThe RequirementOur packaging consultant will contactwith you to clarify therequirements for yourpackaging boxes including size, shape, material,color, technology and printed content. Thesefactors will determine the appearance andfunctionality of your packaging box. |

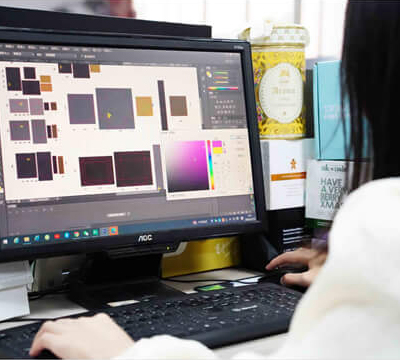

Artwork DesignHere at Huaisheng Packaging, We have ateam ofexperienced andtalented designerswho will work with you to create Packagingartwork that is eye-catching and reflectsyour brand in the bestway possible. |

|

|

Sample productionPrior to mass production, it is customary tocreate samples. it allow you to see howthe final product will look, and can help toidentify any potential problems. ifneeded.make necessary modifications and adjustments. |

|

Printing Process Once the design and materials arefinalized, the printing and processing phase begins.Common printing methods include offsetprinting, UVprinting and screen printing, andanti-scratch oil on the surface; Processing techincludes hot stamping, cutting, gluing boxassemable and other processes. |

|

|

Mass ProductionAfter confirming the final artwork,arrangeproduction and deliverybased on your order quantity and delivery time. |

DeliveryWe provide express, sea, air and othertransportation ways for you to choose from.The delivery time depends on which countryyou from and transportation way. |

|

We Guangzhou Huaisheng Packaging company considers the quality of custom packaging boxes as the most important factor,so we have quality control in the whole production process,especially in the printing process and handmade process.We care about every detail in the process and have professional persons are in charge of each process.Choose us to be your gift box supplier is the most right choice.

Process

Any other requests you requested can be provide also,feel free to inquiry us now!