Contact Us

Contact Us

Guangzhou Huaisheng Packaging Co.,Ltd.

We provide customers with quality products and provide high-quality services.

If you would like to leave us a comment please go to contact us

+86-18122240089

If you want to custom unique packaging boxes for your business, many printing options can be chosen. such as embossing/debossing, UV, foil stamping, and so on. In this article, we will discuss what embossing and debossing are, the difference between them, their applications, and why they can make your packaging box stand out.

Embossing and debossing are two popular techniques used in the packaging industry to enhance the appearance of packaging boxes. These techniques are used to create a three-dimensional effect on the surface of the packaging box, making it more attractive and eye-catching.

The main difference between embossing and debossing is the direction in which the design or pattern is raised or pressed into the surface of the material.

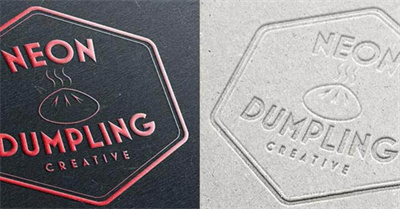

Both embossing and debossing printing effects are done by stamping with a mold or a metal plate. Through the embossing process, the back side of the material is impacted, causing the pattern on the front side to protrude. The debossing process is to press the pattern into the paper to form a concave effect.

Embossing and debossing are widely used in the packaging industry to enhance the appearance of packaging boxes. These techniques are used to create a three-dimensional effect on the surface of the packaging box, making it more attractive and eye-catching. Embossing and debossing can be used on a variety of materials, including paper, cardboard, and plastic.

Embossing and debossing can be used to create a variety of effects on the surface of the packaging box. For example, embossing can be used to create a raised logo or text on the surface of the packaging box, while debossing can be used to create a depressed pattern or design on the surface of the packaging box. These techniques can also be used in combination to create a more complex design or pattern on the surface of the packaging box.

Embossing and debossing can make your packaging box stand out in a crowded marketplace. These techniques create a tactile and visual effect on the surface of the packaging box, making it more creative. A packaging box that has been embossed or debossed will stand out from other packaging boxes that have not been treated with these techniques.

It can also add a sense of luxury and sophistication to your packaging box. These techniques are often used on high-end products to create a premium look and feel. A packaging box that has been embossed or debossed will convey a sense of quality and value to the consumer.

In addition, embossing and debossing can be used to highlight specific features or information on the packaging box. For example, a company logo or product name can be embossed on the surface of the packaging box, making it more prominent and memorable. This can help to increase brand recognition and customer loyalty.

Conclusion

Embossing and debossing are two popular techniques used in the packaging industry to enhance the appearance of packaging boxes. These techniques can make your packaging box stand out in a crowded marketplace, and convey a sense of luxury and sophistication.

If you want to learn more knowledge about the printing process, please follow us;

If you want to create an ideal packaging box for your products, please contact us.