Contact Us

Contact Us

Guangzhou Huaisheng Packaging Co.,Ltd.

We provide customers with quality products and provide high-quality services.

If you would like to leave us a comment please go to contact us

+86-18122240089

As we all know, to make a rigid paper box will need so many processes before packing it into cartons. Such as printing,lamination,foil stamping or other finishing,die cutting,grooving,gluing, assembling,hand making and so on.For paper box supplier,it is very important to know how to make each process smooth and perfect in the limited delivery time.

Die-cutting process is a key point in the process of paper box making processing. In order to obtain the ideal die-cutting effect, besides paying attention to the operation method of the die-cutting process itself, the process control of each process before die-cutting is also very important. This article will discuss this.

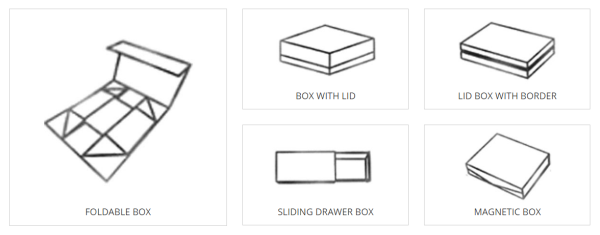

1.Box shape design

Box-shaped design should be based on the contents of the design of the main body size of the gift box. Under normal circumstances, the size of the main body is 2~5mm larger than the outer diameter of the content, which can ensure that the product can be smoothly put into and out of the box, and it also meets the theme of environmental protection in today's society - saving paper.

In the case of a layout for a rigid box that has been determined to have a good body size, proper consideration should be given to reducing the size of the knife at the time of joining and changing the size of the relatively minor parts such as the life and the box tongue to save paper and facilitate subsequent processing. According to the characteristics of die-cutting and gluing equipment of our company, the operator usually reduces the size of the knife to 3mm, and the minimum width of the bread can be reduced to 8mm.

2.Print layout design

The design of the printing layout is closely related to the control of the die-cutting process of the custom gift box. The design is ingenious to a certain extent determines the ease of die-cutting process. The best design should have a good idea, but also be able to facilitate printing and post-press processing. For example, you should avoid designing products with extremely high requirements for plate joining, because in this case, as long as the paper is slightly deformed or slightly misaligned when it is die-cut, quality problems will occur.

3.Paper selection

When die-cutting into finished boxes, we often find that the quality of some paper boxes does not meet our expectations. Often, customised paper box packaging are too soft, not strong enough, or the cardboard boxes are not square enough. The reason is usually the paper we choose less than the quality requirements of the product, or the choice of paper silk direction is not appropriate. Only the direction of the paper's skein is perpendicular to the main processing line of the box can get a more square shape. For products that require paper-to-edge or corrugated, the vertical intersection of the paper and the bottom paper must also be ensured. For a corrugated mailing box, you should also make sure that the corrugation is oriented perpendicular to the paper tray.