Contact Us

Contact Us

Guangzhou Huaisheng Packaging Co.,Ltd.

We provide customers with quality products and provide high-quality services.

If you would like to leave us a comment please go to contact us

+86-18122240089

In today's competitive market, the presentation of a product can be as important as the product itself. Custom gift boxes play a vital role in enhancing the unboxing experience, making your brand memorable, and adding a touch of luxury. But how does custom gift box production work? This article will delve into the intricate process, answering frequently asked questions and providing valuable insights into each step involved in creating these exquisite packaging solutions.

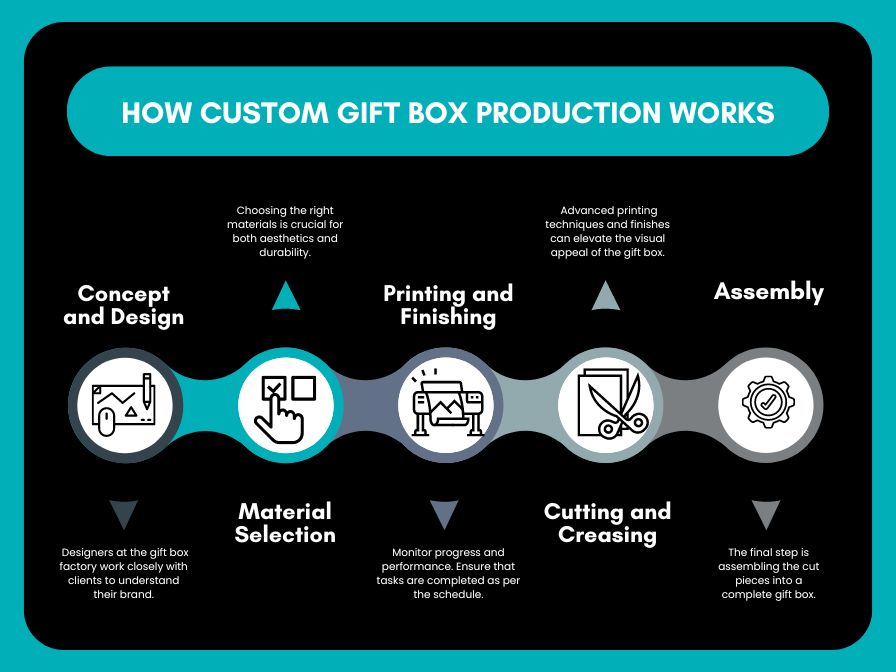

Custom gift box production is a detailed and multi-step process that involves designing, material selection, printing, cutting, and assembly. Each stage requires precision and creativity to ensure the final product meets the highest standards of quality and aesthetic appeal. At a gift box factory, these processes are streamlined and optimized for efficiency and quality.

The journey begins with the concept and design phase. This is where the vision for the custom gift box comes to life. Designers at the gift box factory work closely with clients to understand their brand, target audience, and specific requirements. Key considerations include:

Choosing the right materials is crucial for both aesthetics and durability. Common materials used in custom gift boxes include:

The choice of material can significantly impact the look and feel of the gift box, as well as its sustainability. A reputable gift box factory will offer a variety of material options to meet diverse needs.

Printing is where the design gets transferred onto the chosen material. Advanced printing techniques and finishes can elevate the visual appeal of the gift box. Common methods include:

At a professional gift box factory, state-of-the-art printing technology ensures precise and vibrant results.

Once printed, the materials are cut and creased according to the design specifications. Precision is key in this stage to ensure that the pieces fit together perfectly during assembly. Modern machinery and technology at the gift box factory enable accurate cutting and creasing, reducing waste and improving efficiency.

The final step is assembling the cut pieces into a complete gift box. This can be done manually or using automated processes, depending on the complexity and volume of the order. Quality control checks are essential to ensure that each box meets the required standards. A well-organized gift box factory maintains strict quality assurance protocols to deliver flawless products.

The production time can vary depending on the complexity of the design and the volume of the order. On average, it takes about 2-4 weeks from concept to completion. A reliable gift box factory will provide accurate timelines and efficient service.

MOQs can vary between manufacturers. Some may offer low MOQs of 100-500 units, while others may require larger orders of 1000 units or more. A flexible gift box factory will cater to different business sizes and needs.

Absolutely! Most manufacturers, including professional gift box factories, allow you to provide your own designs, or you can work with their design team to create something unique.

Yes, many manufacturers offer eco-friendly options such as recycled cardboard and biodegradable materials. A responsible gift box factory will have a range of sustainable materials to choose from.

The cost depends on several factors, including the materials, design complexity, printing techniques, and order volume. It's best to get a quote from the manufacturer based on your specific requirements. A reputable gift box factory will offer competitive pricing and detailed quotations.

Custom gift box production is a fascinating blend of creativity and technical expertise. From concept and design to material selection, printing, cutting, and assembly, each step is crucial in creating a product that not only protects but also enhances the value of the gift inside. By understanding the intricacies of this process, you can make informed decisions that will elevate your brand and delight your customers. Partnering with a professional gift box factory ensures high-quality results and a seamless production experience.