Contact Us

Contact Us

Guangzhou Huaisheng Packaging Co.,Ltd.

We provide customers with quality products and provide high-quality services.

If you would like to leave us a comment please go to contact us

+86-18122240089

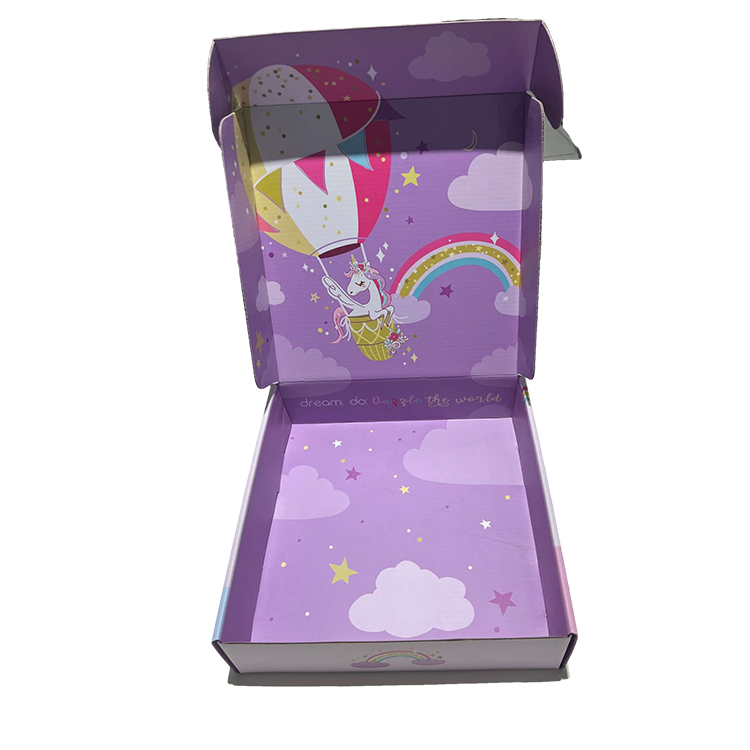

Now the widely used packaging boxes are corrugated cartons, generally used in health care products packaging cartons, cosmetics packaging and other different industries.

Cartons are generally divided into corrugated boxes, single layer cardboard boxes, etc., and many other specifications and models. Here is to introduce the knowledge of corrugated boxes.

Corrugated carton with its unique hardness gradually replaced the past wooden box packaging, the sales is in the first of the packaging products.

Corrugated cardboard box is made of corrugated cardboard after die cutting, printing, indentation, nail box (or sticky box) made of a large hardness of paper packaging.

As we all know, in addition to the protection of goods, cartons can also reflect the information of goods, facilitate the identification and storage of goods, which requires the printing of cartons.

There are two main carton printing methods and production methods: carton ink printing and ink color printing.

General corrugated of the same material, thickness and stiffness is inversely proportional.

As the main body of the carton, corrugated board is commonly used for A, B, C, E and F, and the thickness decreases successively, with A being the thickest and F the thinnest.

1. Corrugated board → printing → slotting → nail box → adhesive box or direct packaging delivery

2. corrugated board → printing → die cutting → nail box → adhesive box or direct packaging delivery

3. corrugated board → printing → slotting → die-cutting → adhesive box → packaging automatic molding

Design corrugated boxes, generally consider three dimensions: internal size, external size and manufacturing size.

Manufacturing size = external size - coefficient (coefficient generally depends on the number of layers and materials of cardboard)

Generally, outer size = inner size *2* cardboard thickness (considering the thickness loss in the actual manufacturing process)

In reality, the up and down deviation should be adjusted reasonably according to the characteristics of different customers